Recent News

Foundation Repair Technologies

ASCE Press Release

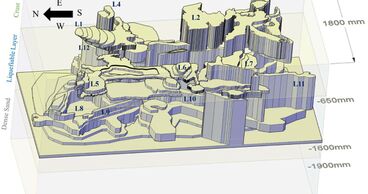

Heavy Rains in California

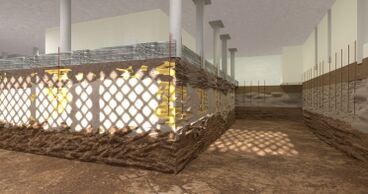

Polyurethane in Foundation Repair

Thank you for your interest in EagleLIFT job opportunities

Questions? Contact info@eaglelifting.com

EagleLIFT uses Indeed, Ziprecruiter and our Website for the purposes of advertising open positions and accepting applications. EagleLIFT does not use other social media sites to advertise for open job positions. If you wish to authenticate a job posting you saw online you may contact us at info@eaglelifting.com and we'll verify whether it was an EagleLIFT sponsored post or spam. Thanks again for your interest.

Download Free Foundation Repair Guide

Dealing with foundation problems can be stressful. Something that can help is being aware of the signs of foundation settlement and educating yourself on the basics of foundation repair technologies. This guide will show you the most common foundation problems and the repairs that are most likely to be recommended by foundation contractors.